FLOW DIVIDERS

Are you in search of a Vivoil flow divider for your project and need guidance on choosing the right one? Here’s a comprehensive guide to assist you in selecting the ideal flow divider and understanding the key features that will ensure optimal performance for your application.

This guide also includes tips for maintaining the component’s efficiency, examples of custom configurations we’ve crafted for other clients, installation instructions, and information on specialized applications.

What is a flow divider and what is it used for

A flow divider is a hydraulic component designed to divide or reunify oil flow into predetermined ratios, which may be equal or different.

The three main functions of a divider are:

- Dividing the oil flow.

- Unify flows to regularize different oil flow rates (combine flow).

- Multiply the pressure

The VBC Hydraulics range includes 4 models of dividers

Various types of flow dividers are available in the market. Our range of flow dividers, in particular, includes 4 models: 3 of these are traditional flow dividers (valveless, single-valve, multiple-valve), the fourth is our self-compensated flow divider MIA-FD.

1

Flow dividers without valves

What are they for

Dividers without valves can be used to divide or combine flow and multiply pressure.

Recommended when

The design involves movements with non-high frequency (few cycles).

2

Single-relief valve flow dividers

What are they for

Single valve dividers can be used to divide or combine the flow and multiply the pressure.

Recommended when

The design requires reset of the error, given the frequency of cycles, to avoid a cumulative effect, but at the same time you are looking for a component that is easy to adjust. In this version, all that is needed is to act on the one valve in the divider to allow end of stroke rephasing of all elements.

3

Flow dividers with multiple releasing and anti-cavitation valves

What are they for

Flow dividers with multiple releasing and anti-cavitation valves can be used to divide or combine flow and multiply pressure.

Recommended when

The design requires the error to be zeroed in both directions (both in splitting and reunification ). In fact, this model has both a relief valve and an anti-cavitation valve for each element.

4

Manifold Instantaneous Auto-compensating Flow Dividers (MIA-FD)

What are they for

MIA-FDs distribute and feed the different sections of the circuits with constant flow rates. It can only be used to divide or combine the flow and not as a pressure multiplier.

Recommended when

The project includes highly unbalanced conditions.

This model handles the different loads on the actuators while maintaining optimal division even under these conditions.

It also works as a manifold equipped with CETOP 3 connections on each element, making it a compact and expandable solution.

Want to learn more about the features and possibilities of this model? Read our in-depth article on the MIA-FD flow divider.

Beware of imitations!

Flow dividers similar to ours are for sale on the market, produced by companies with whom we have no relationship: these are imitations. To recognize our original products from counterfeit ones check:

the label (all VBC Hydraulics products since 2010 have a label that is very difficult to remove)

the trademark (all our components are engraved with the VBC HYDRAULICS trademark)

You can learn more about the characteristics of our components in the article on how to recognize original VBC Hydraulics flow dividers from imitations.

Beware of imitations!

VBC Hydraulics dividers can have different displacements and pressure ranges and are divided into 4 size groups:

- Group 0 (Displacement 0.16 cm3/rev – 2.28 cm3/rev, maximum pressures up to 210 bar)

- Group 1 (Displacement 0.91 cm3/rev – 9.88 cm3/rev, maximum pressures achieved up to 220 bar)

- Group 2 (Displacement 4.2 cm3/rev – 39.6 cm3/rev, maximum pressures achieved up to 210 bar)

- Group 3 (Displacement 14.89 cm3/rev – 86.87 cm3/rev, maximum pressures reached up to 300 bar)

Depending on your project, you can choose the most suitable group or in many cases even combine multiple size groups.

How to choose the best VBC Hydraulics flow divider for your project

Valveless, single-valve, multi-valve, or MIA-FD: which type of VBC Hydraulics flow divider should you choose for your project? To identify the most suitable one, follow these steps:

- Define the flow rate of each element and calculate the displacement (here is how to calculate the displacement of a divider knowing the flow rates)

- Choose the size group based on the displacement and pressures (0, 1, 2, 3)

- Evaluate the model based on the application

To learn more about all these aspects and to evaluate the best size group for you, read our in-depth article on how to choose a flow divider where you will find formulas, tables and other useful tips.

Customize your VBC Hydraulics flow divider

Once you have identified the model for you, you can customize it, choosing from the many options available, combining different size groups or selecting one of the configurations we have already made.

1

Speed sensor or outgoing shaft

You can choose either one or the other, because they are alternatives. These two options can be integrated only into dividers without valves.

- The speed sensor is one of the newest accessories we have introduced that we can supply together with the divider so that you can install it. It is a sensor built into the divider, which reads the passage of the gear and gives a pulse. It can be used, for example, to check that the lubrication system is moving.

- The outgoing shaft is the alternative solution. Externally to the divider, in fact, a phonic wheel can be attached to the shaft, which allows the rotation to be read, or as a small power take-off (obviously without axial/radial loads).

2

Motor

You can expect this configuration if you have single-acting cylinders in your design when, on descent, not enough load is applied. The motor, in fact, negates the starting pressure required to move the divider. To learn when to apply it and how to size the motor, read our in-depth article on flow dividers with motor.

3

Electrically operated valves (or solenoid valves)

This option allows you to stop or send the oil flow to drain at any time, via an electrical pulse, without having to wait for pressure changes or for the cylinders to reach the end of their stroke. It therefore allows you to activate the rephasing whenever you want. To learn about all the features and possibilities of this option, read our article on flow dividers with electrically operated valves.

4

Viton

It is an option that allows you to manage special conditions of temperature and oil compatibility

5

Internal drainage

It simplifies the circuit by removing the discharge line to the tank, but it is inadvisable because it stresses the system and makes valve calibration more complicated.

It also inhibits the rephasing function during reunification for models equipped with anti-cavitation valves.

One more option: choose from different combinations of size groups

You also have the option of combining dividers of different size groups – for example, a divider with elements from group 0 and group 1, a divider with elements from group 1 and group 2 – so that you can handle very different output flow rates.

For these special conditions contact us for the optimal solution.

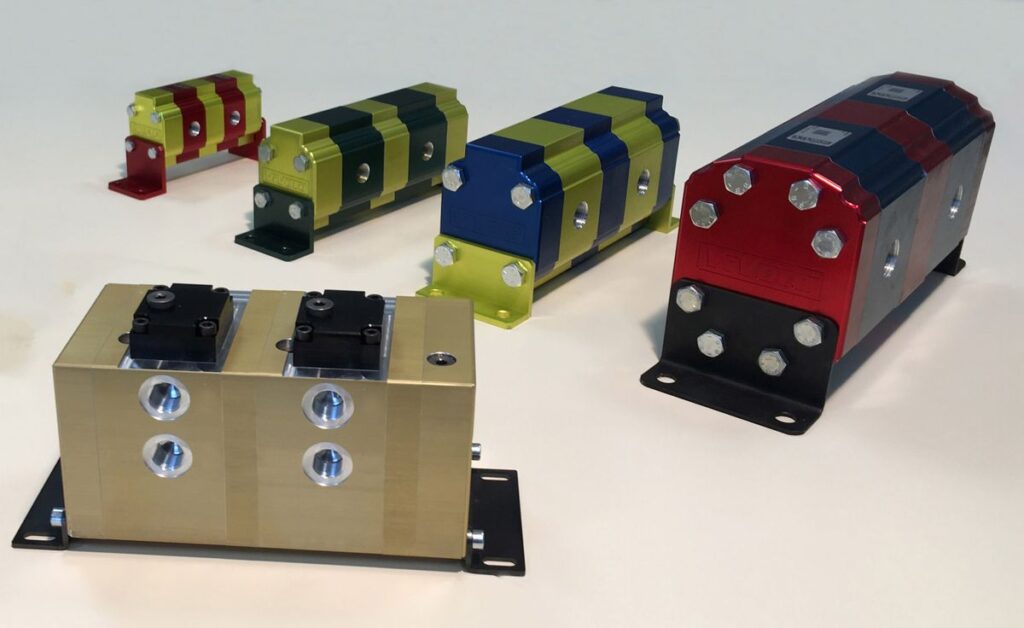

Our custom configurations

In addition to the customizations just shown, you can also evaluate one of the configurations we have already made for our clients:

- Absent mounting brackets

- Brackets in non-standard positions

- Side input door

- Number of input ports different from the standard

- Version with equal number of inputs and outputs to rebalance flow rates

- Flow Divider provision for you to complete with valves, but supplied without valves (useful if you want to apply a valve that is not in our catalog)

- Color customization (for large batches)

- Custom labeling and special markings, such as logos and lettering (for large batches)

How to install the VBC Hydraulics flow divider and directions for use

Having chosen the divider, here are the steps to install it and some tips for its maintenance.

1

Installing a VBC Hydraulics flow divider

1 ) Cleaning and preparation

- Thoroughly clean the pipes and the component

- Verify that the pipes are the correct length with respect to the system

- Check that the fluid used is suitable for the divider

2) Connection and startup

- Connect the pipes to the divider

- Start the flow divider

3) Calibration of power factor correction valves

- Check for proper drainage installation (under the oil head for multivalve version)

- Perform valve calibration

Valve calibration is a very important step for the flow divider to function properly, to avoid operating errors and numerous problems, including component failure. In fact, the flow divider valves intervene at the end of the stroke to reset the error and must be adjusted to open at the right time. Calibration changes depending on the type of valves.

2

Changing the Valve Range

Valve range adjustment depends on the resistance of the spring inside the valve. To change it, simply replace the spring with one of a different size, but the procedure changes depending on the component.

In our in-depth article on how to change the range of VBC Hydraulics valves, you will find all the directions for changing the range of valves:

- LPA 10 and LPB 10 in the VBC Hydraulics components of group 0

- LPB 20 and LPS 20 in the VBC Hydraulics components of groups 1 and 2

- LPA 30 and LPB 30 in the VBC Hydraulics components of group 3

3

Oil Cleaning and Filtering

When installing, be sure to use compliant hydraulic fluids, verifying that their viscosity is compatible with that indicated in our catalogs. In fact, using different fluids could damage the divider. We also advise you to check that the filters are installed according to the following directions:

| Working Pressure Bar | Δp Lower Than 140 | Δp Between 140 and 210 | Δp Higher Than 210 |

|---|---|---|---|

| Contamination Class NAS 1638 | 10 | 9 | 8 |

| Contamination Class ISO 4406:1999 | 21/19/16 | 20/18/15 | 19/17/14 |

| To Be Obtained with Filter ß10 (c) ≥ 200 According to ISO 16889 | – | 10 μm | 10 μm |

| To Be Obtained with Filter ß25 (c) ≥ 200 According to ISO 16889 | 25 μm | – | – |

Maintenance and Repair of the Flow Divider

To check the proper functioning of the flow divider you have installed, we recommend that you periodically check that:

- The screws are tightly tightened

- There is no leakage between the elements

- The error is around what is reported in the plant design data

If the error increases over time, it could be due to product wear and tear and you may have to consider replacing it.

How to Replace the VBC Hydraulics Component You Already Have with a New One

Flow dividers are provided with labels identifying the product to request any replacement.

If you have a VBC Hydraulics product from the old KV series that has come to the end of its life and you need to replace it with a new divider from the current RV series, it is important that you know that the KV and RV series dividers are different. To figure out which component to choose, several factors should be considered:

- Whether the divider is with or without valves

- Whether the footprint is sufficient for the new divider

- Where the inputs are located

Find all the guidance in our in-depth article on how to replace a KV flow divider with an RV flow divider.

Most Common Problems in Using the Divider

One of the most common problems that can occur using a flow divider is cylinder misalignment. If the error is less than 3%, this is a physiological condition: no matter how accurate, an error is always present in all flow dividers. For larger errors, however, the problem could originate from various elements, including load differences.

Have you checked but the load difference is less than 30 bar and the valve calibration is correct? Then it is possible that the misalignment of the cylinders is due to problems with the system:

- Air in the system

- Error in exhaust connection

- Lack of rephasing, which led to a cumulative error

- Incorrect divider sizing

- Damage to seals

Special Applications of Our Dividers (Out of Common Use)

- To balance flow rates

- As a pressure multiplier (a useful application if you want to optimize the energy consumption of a system and reduce its waste by harnessing the residual hydraulic power of a flow, simply by sending part of it to drain)

Our products

Hydraulic pumps

They are made of aluminium and with external gears, but some components are also available with cast iron flanges. You can choose between unidirectional motors and reversible motors. The capacity of these products varies between 0,45 cm3/rev and 86,87 cm3/rev.

Hydraulic motor

They are made of aluminium, with external gears, and modular even over 20 elements. We can assemble some types of flow dividers with elements of different size groups, in order to handle even flows that are very different from each other. The capacity of these products varies between 0.16 cm3/rev and 86.87 cm3/rev.

Flow Dividers

They are made of aluminium and with external gears, but some components are also available with cast iron flanges. You can choose between unidirectional pumps, reversible pumps, multiple pumps or multiple pump stages. The capacity of these products varies between 0.16 cm3/rev and 86.87 cm3/rev.